Restoring Reliability On The Canning Line

with MITRPAK Right Angle GearboxIn an unassuming industrial park just off the Garden State Parkway, something exciting is brewing. It’s not just the waft of hops or the hum of fermenters that grabs your attention, but also the symphony of machinery in motion.

Icarus Brewing, nestled amidst Lakewood’s industrial heart, isn’t just churning out artisanal ales—it’s rewriting the rulebook on brewery operations.

With a rapidly growing community of small-to-midsize craft brewers driving demand, the modern canning line is elevating the interplay between machinery design and component synergy to new heights. This dedication to efficiency empowers Icarus Brewing to thrive within its modest footprint, emphatically declaring that a brewery’s impact isn’t dictated by its scale. Central to this dynamic, propelling the production line with tenacious reliability, is the MITRPAK right-angle gearbox.

Icarus Brewing

Occupying a 4,000-square-foot space in an industrial hub, Icarus Brewing represents what effective machinery design and floorplan optimization can achieve. With an impressive production capacity of around 5,000 Barrels, translating to 155,000 gallons annually, the brewery has carved a niche for itself in the highly competitive craft beer industry. This scale of production is made possible through a 10-barrel brew house, producing 310 gallons per batch. Moreover, the establishment doesn’t just facilitate brewing; it also houses a vibrant tasting room, presenting logistical challenges that demand a keen sense of space management. Every inch of the facility and every machinery component must perform to keep pace with their ambitious operational targets.

Canning days at Icarus Brewing can be a major event. With space at a premium and no permanent canning line in the facility, the taproom is temporarily closed to allow the setup of a portable canning machine. These processes are meticulously scheduled to ensure minimal disruption to the taproom schedule, and any unexpected issues could compound production line downtime with the additional loss of business due to an extended taproom closure.

Craft Brewery Equipment Solutions: MITRPAK’s Impact

During a routine canning day, as the canning line inched toward its two millionth can, the brewing operations faced a sudden mechanical setback that brought the process to a grinding halt. The immediate diagnosis was concerning; the gearbox had suffered a significant break. This wasn’t just a minor glitch— it presented a potential ripple effect that would impact their entire production schedule.

Knowing a halt in their production due to a gearbox malfunction would disrupt taproom operations, they contacted the gearbox experts at MITRPAK in search of a fast solution. Ed Burch, a seasoned MITRPAK employee-owner with an extensive background in gear drives, immediately took the helm. He understood the urgency of the situation and quickly sourced a replacement gearbox identical to the original model. The MITRPAK right angle gearbox was a direct fit for their Codi 6-head canning machine, minimizing the likelihood of extended downtime. The replacement was in the hands of the Icarus team in under 24 hours, preventing a potentially catastrophic delay in their tight production schedule.

Knowing a halt in their production due to a gearbox malfunction would disrupt taproom operations, they contacted the gearbox experts at MITRPAK in search of a fast solution. Ed Burch, a seasoned MITRPAK employee-owner with an extensive background in gear drives, immediately took the helm. He understood the urgency of the situation and quickly sourced a replacement gearbox identical to the original model. The MITRPAK right angle gearbox was a direct fit for their Codi 6-head canning machine, minimizing the likelihood of extended downtime. The replacement was in the hands of the Icarus team in under 24 hours, preventing a potentially catastrophic delay in their tight production schedule.

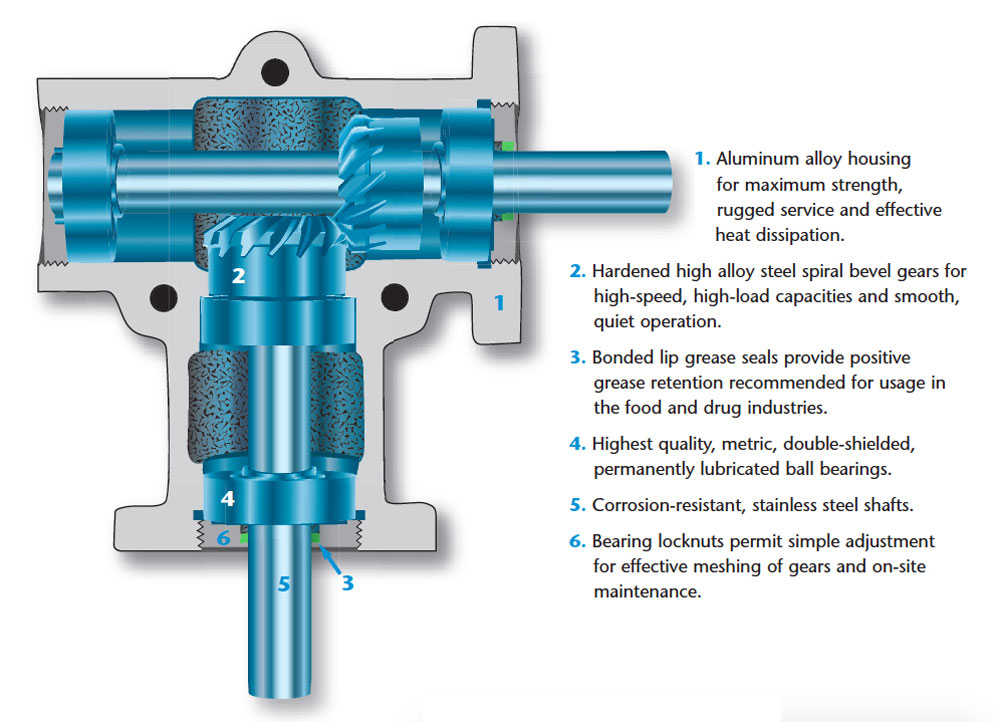

Within the canning mechanism, the gearbox assumes a pivotal role. It handles the vertical shaft operation, spinning a cog attached to a belt that propels an auger through the machine. This process is vital for efficiently filling and sealing the cans, and any deviation can result in reduced throughput and consistency. Given that the canning line is frequently repositioned due to space constraints, the durable MITRPAK gearbox was the perfect component to ensure strength and durability without compromising performance.

However, the support from MITRPAK continued beyond expedited gearbox replacement. MITRPAK’s team delved deeper into the operational environment of Icarus Brewing’s canning line. They determined that this model, though physically compatible, wasn’t ideally suited for a brewery’s demanding conditions—namely, the caustic washdowns and the consistently wet and challenging environment of the canning process.

In response to this insight, MITRPAK took a proactive step. They recommended a model designed specifically for food and beverage processing with food-grade lubrication and double seals that would fit the existing gearbox footprint and better withstand the challenging conditions of typical brewery operations. With a better gearbox for canning operations in hand, company president John Biagioni and Director of Engineering Rick Caponi set out to visit Icarus Brewing in person. Once the part was delivered, they enjoyed a tour of the operations and a frosty beverage— all in the name of due diligence, of course!

Food-Safe Gearboxes for Breweries

By integrating MITRPAK’s food-safe right-angle gearbox into the canning line, Icarus Brewing substantially elevates its production capabilities and operational efficiency. This strategic upgrade harnesses the gearbox’s corrosion-resistant, hard-coat anodized aluminum housing, ensuring unmatched durability and resilience against the rigorous conditions of beverage processing. The sealed, maintenance-free design eliminates contamination risks and the necessity for re-lubrication, streamlining operations and safeguarding the brewery’s commitment to product purity.

Opting for a gearbox packed with food-grade lubricant not only aligns with FDA guidance recommendations but also exemplifies Icarus Brewing’s dedication to upholding the highest standards of food safety.

The precision engineering of MITRPAK® gearboxes, featuring adjustable lock nuts for precise adjustments, enhances the canning line’s reliability and extends its operational life, reducing downtime and maintenance demands. Furthermore, the gearbox’s ability to withstand extreme cleaning methods protects the investment and ensures consistent, high-quality output. This transition to a food-safe MITRPAK gearbox marks a small yet significant step forward for Icarus Brewing, driving efficiency, ensuring regulatory compliance, and, ultimately, reinforcing their reputation for quality and safety in the competitive craft beer market.

Custom Gearboxes for Food and Beverage Processing

The initial replacement unit allowed Icarus Brewing to resume production schedules without missing a beat. This rapid response underscored MITRPAK’s commitment to their clients’ immediate needs. Yet, by identifying and supplying a more suitable sealed model for future use, MITRPAK demonstrated a deeper level of support, focusing on both the urgent need and the long-term success of Icarus Brewing’s operations.

The initial replacement unit allowed Icarus Brewing to resume production schedules without missing a beat. This rapid response underscored MITRPAK’s commitment to their clients’ immediate needs. Yet, by identifying and supplying a more suitable sealed model for future use, MITRPAK demonstrated a deeper level of support, focusing on both the urgent need and the long-term success of Icarus Brewing’s operations.

Upon integrating the new MITRPAK gearbox, Icarus Brewing saw an immediate restoration of production efficiency. The canning line exhibited no lag or reduction in speed, allowing the team to resume their demanding production schedule with minimal delay. This rapid bounce-back is a clear demonstration of the efficacy of the MITRPAK unit. It highlights the importance of choosing components that are functionally robust and supported by the manufacturer in dire situations.

Any disruptions in machinery, especially in a setting as streamlined as Icarus Brewing, can lead to cascading bottlenecks, jeopardizing production schedules and output. In this context, the seamless integration of the MITRPAK gearbox underscored its reliability and its crucial role in ensuring that production continued unhindered.

Craft Brewery Equipment Solutions: MITRPAK’s Impact

With their minds set on the future, Icarus Brewing is looking at plans for expanding operations. This impending growth underscores the need for machinery and components that can sustain and boost their current efficiency levels. The integration of the initial MITRPAK gearbox enabled Icarus Brewing to resume production right away. This seamless transition was a testament to MITRPAK’s quick and effective response. But the story didn’t end there; the anticipation of integrating a gearbox model better suited to the brewery’s wet environment adds a layer of operational security and efficiency for the future.

This two-pronged approach to support from MITRPAK—addressing both the immediate need and providing a longer-term solution—highlights the importance of selecting machine components specifically tailored to meet the unique demands of the application. For Icarus Brewing, this means not only can they trust in the reliability of their machinery today, but they can also look forward to enhanced operational stability and efficiency with the upgraded right-angle gearbox.

In environments as dynamic and demanding as that of Icarus Brewing, the right support can make all the difference. MITRPAK’s approach—swift action followed by thoughtful, customized solutions—exemplifies a partnership that goes beyond mere transactional interactions, aiming instead for enduring reliability and success.

Elevate Your Beverage Processing Equipment with MITRPAK

MITRPAK’s right-angle gearboxes offer unparalleled reliability, efficiency, and food safety compliance. Embrace the same innovative solutions that propelled Icarus Brewing to new heights and see how our custom gearboxes can revolutionize your equipment.

Let’s craft the future of beverage processing together—innovation starts here.