Recently, a MITRPAK customer called on our Engineering Director, Rick Caponi, with an interesting challenge that required some creative thinking. The customer needed a custom gearbox solution for a conveyor system driving two separate belts in parallel as part of a chub packaging system. After some ingenious collaborative engineering, Rick and his customer devised a solution that would reduce the machine builder’s cost and improve the machine’s performance.

Chub Clipper or Beef Slicer – Get the Power You Need With MITRPAK

This style of packaging is named for its origins in butcher shops, where they would wrap ground meat in long tubes of waxed paper for easy storage and transport. Today, however, the word is applied to describe the form rather than the contents, and chub packaging equipment has proven to be a highly effective packaging method for industries ranging from food service to construction. Chub packaging is often composed of plastic or metalized film with clips at each end to form a rounded cylinder and is typically filled with product using standard vertical-fill vacuum-seal equipment.

This style of packaging is named for its origins in butcher shops, where they would wrap ground meat in long tubes of waxed paper for easy storage and transport. Today, however, the word is applied to describe the form rather than the contents, and chub packaging equipment has proven to be a highly effective packaging method for industries ranging from food service to construction. Chub packaging is often composed of plastic or metalized film with clips at each end to form a rounded cylinder and is typically filled with product using standard vertical-fill vacuum-seal equipment.

This customer’s design utilized a horizontal conveyor to drive product toward the filling chute. The custom conveyor system forms a V-shaped trough that transports filling materials. This allows for high-efficiency movement by reducing friction and drag, making it especially useful when dealing with heavier objects or bulk items.

A large spiral bevel gearbox was selected from the MITRPAK line with the power and coordination to drive the dual belts in unison. The spiral bevel gearbox transfers rotational motion from a motor to the drive shaft of the conveyor. As the name suggests, this type of gearbox uses bevel gears arranged in a helical pattern, which allows for smooth and efficient operation.

The advantages of using a spiral bevel gearbox include increased torque capacity due to its design, improved efficiency thanks to its low friction levels, and small size which makes it easier to install and maintain. Additionally, since these devices feature high load-carrying capacity they can handle heavier materials with ease – making them an ideal choice for transportation applications such as chub sausage packaging systems.

Innovative Engineering & Powerful Solutions for Your Unique Food Processing Needs

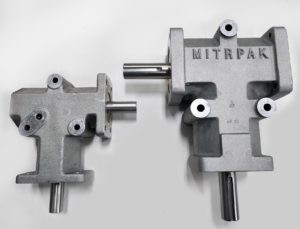

“This was a really unique, innovative way to use MITRPAK gearboxes. The first time I thought about a gearbox to be used to drive two belts at an angle like that,” said Caponi. The problem with the customer’s design came down to the large, high-powered gearbox he had selected: “He showed me a design with pulleys, custom machined parts, and our gearbox– but he needed the MITRPAK shafts to be shorter. I looked into it but there was no way to tighten up the spacing on that big unit. I looked at his sketch and realized that he didn’t need such a large model, and instead of shortening the shaft on the oversized model, we were able to extend the shafts on a model with a much smaller footprint, lower weight, and lower cost.”

“This was a really unique, innovative way to use MITRPAK gearboxes. The first time I thought about a gearbox to be used to drive two belts at an angle like that,” said Caponi. The problem with the customer’s design came down to the large, high-powered gearbox he had selected: “He showed me a design with pulleys, custom machined parts, and our gearbox– but he needed the MITRPAK shafts to be shorter. I looked into it but there was no way to tighten up the spacing on that big unit. I looked at his sketch and realized that he didn’t need such a large model, and instead of shortening the shaft on the oversized model, we were able to extend the shafts on a model with a much smaller footprint, lower weight, and lower cost.”

The design was revised to use the next size down– the T 121. The customer could save time, money, and effort by switching out the gearbox for a smaller model. This would also improve the serviceability of the equipment by allowing a roomier fit. With MITRPAK’s ability to customize shaft lengths in their gearboxes, customers can get exactly what they need without compromising on performance or reliability.

MITRPAK Meets Your Requirements

The success of this creative solution lies in MITRPAK’s engineering knowledge and collaborative approach with customers. A larger distributor would barely notice selling a large and expensive gearbox that may not have been necessary for this particular job. But MITRPAK’s “just right” sized service means our engineers are only a call away with their extensive product knowledge, ready to work with customers who need customized solutions.

This is why MITRPAK continues to be an industry leader— because we understand that one size doesn’t fit all when it comes to engineering solutions. Through conversations, creativity, and engineering expertise, our engineers have unlocked solutions that many others wouldn’t even consider possible. With a knack for customer service and an eye for innovation, MITRPAK is helping food processing customers take operations to new heights with a range of powerful, customizable power transmission solutions.

If you’re looking for a reliable and innovative power transmission solution for your food processing needs, look no further than MITRPAK. Our experienced engineers are ready to work with you to create the most effective solution possible. From conveyor belts to chains, sprockets and more, MITRPAK has the parts you need for a successful installation. We also offer comprehensive support services ranging from engineering consultation to on-site maintenance and repair. Contact us today to learn how our power transmission solutions can help meet your food processing needs!