Loud, noisy gears can signify mechanical deficiencies that may contribute to poor equipment performance and shortened drive life. The primary contributing factor to gear noise is backlash, defined as the measure of the distance between meshing gear teeth. The greater the backlash, the louder the impact when the gear teeth meet.

Loud, noisy gears can signify mechanical deficiencies that may contribute to poor equipment performance and shortened drive life. The primary contributing factor to gear noise is backlash, defined as the measure of the distance between meshing gear teeth. The greater the backlash, the louder the impact when the gear teeth meet.

Gear Backlash Can Shorten Equipment Lifespan

A suitable amount of clearance is required to allow gear teeth to mesh without binding and to allow a thin film of lubricating fluid to enter between the teeth. However, excessive backlash can contribute to gear noise and motion loss, which makes it difficult to achieve accurate positioning in certain systems. If left unchecked, backlash can ultimately lead to physical damage of the gear teeth, reducing drive lifespan.

Excessive backlash can be caused by gears that are not built to be adjustable; this results in less traction and increased mechanical damage to the system. Manufacturers generally assemble gears with an approximate distance between the gear teeth. They then close the gap just enough to achieve a minimal acceptable tolerance before locking each gear permanently into place with a shim or retaining ring. Unfortunately, with this method, even a minor variation in the manufacturing process can substantially increase the backlash on an individual gearset.

Unique Spiral Bevel Design and Adjustable Locknut Ensure Precise Motion Profiles

Unique Spiral Bevel Design and Adjustable Locknut Ensure Precise Motion Profiles

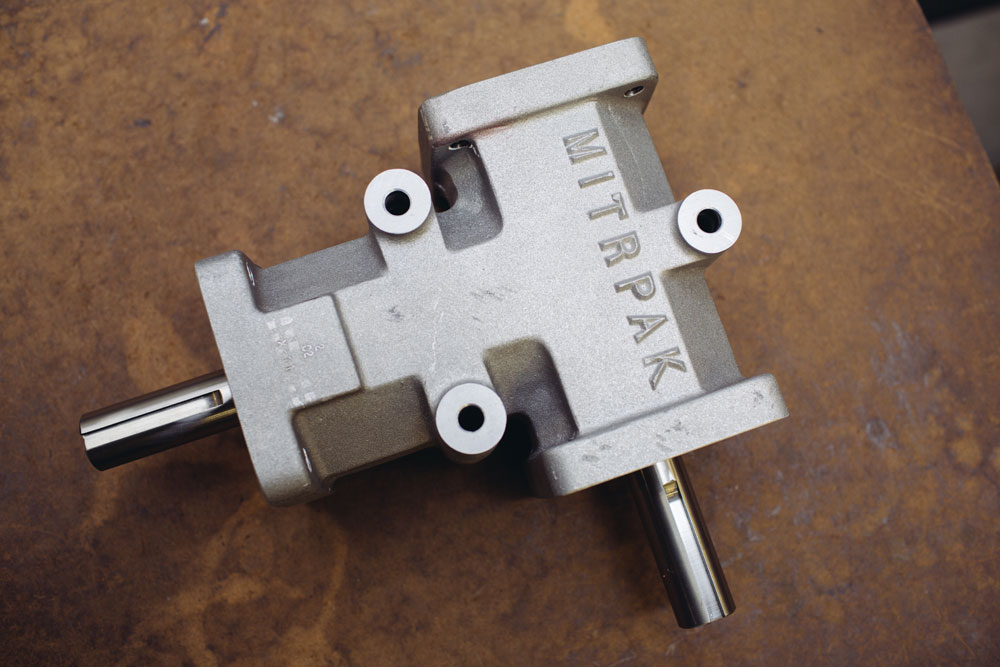

The MITRPAK® spiral bevel gear design eliminates the need for any shims or rings. Its unique, adjustable locknut allows each gearset to undergo extremely precise adjustment by hand. The result is absolute, minimal backlash and smooth, quiet operation.

MITRPAK® spiral bevel gear drives are an advanced type of right-angle drive. They function as important motion-control components of equipment for packaging, food processing, military, textile, agricultural, and a wide variety of material handling and marine applications. For machinery operating at slower speeds and lighter loads, straight bevel gears may be adequate, although their abrupt transfer from tooth to tooth tends to create higher impact stress and greater noise. By contrast, spiral bevel gears are designed so that their curved teeth come into contact gradually.

MITRPAK Spiral Bevel Gearboxes Made in the USA and Built to Last

Can your drive vendor make the necessary adjustments to fully minimize gear noise and backlash? At Lampin, we specialize in producing the innovative, MITRPAK® spiral bevel right-angle gear. Its unique, adjustable locknut and spiral bevel design is the ultimate way to eliminate unnecessary gear noise and backlash, helping to extend the life of your drive. Call us today to learn more.