In the early stages of product design, an engineer will consider the tasks and functions of the machine in development and specify components that can achieve specific torque, speeds, and power ratings, while meeting other ‘secondary’ requirements such as size and placement within a system. When selecting a right angle gear drive as part of a larger mechanical system, choosing the correct size and rating helps to ensure the equipment will function as intended.

Most design specifications will demand a right angle gear drive that meets certain torque and power requirements based on the production run or application. Without the necessary torque or power, the equipment may not be able to meet production needs, or may experience malfunctions that cause unnecessary downtimes. While it is entirely possible that any standard, off-the-shelf right angle drive might be compatible with your design, it’s unlikely that it will be the optimal choice— which is why it’s so important to work with a trusted vendor who will customize a gearbox that meets your unique power and torque requirements perfectly.

Accurately Assessing Your Right Angle Gear Box Power and Torque Requirements

Before contacting a vendor, you should perform an in-depth assessment of the operating environment, specifications, regulations, and requirements of your application. You’ll want to evaluate the following:

- Power requirements for the application

- Torque ratios

- Location of the motion control components to perform maintenance and adjustments

- Environmental temperatures that may impact operations

- Chemicals and cleaning processes that the drive must undergo

- Special local, state, or federal regulations based on facility processes

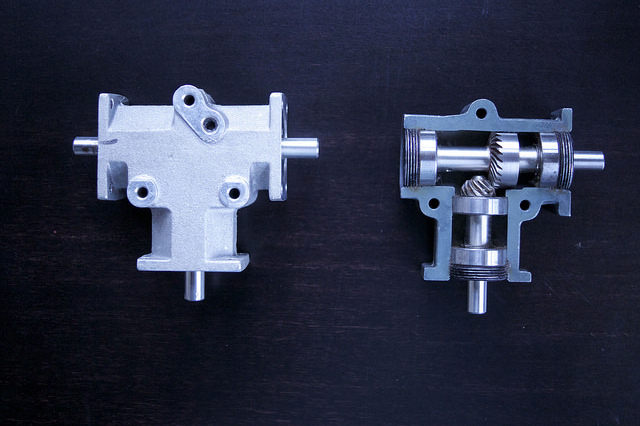

These aspects should be discussed with the vendor so that the design specifications can be customized, with special attention to torque ratios. The torque ratio is determined by the RPM under a set horsepower. Frequently the amount of torque a drive will experience is underestimated— in some cases to a catastrophic degree— causing undue strain and premature fatigue, including teeth wear, bearing failure, or shearing.

If your equipment has suffered damage or failure in the past, discussing these failures with your vendor can also be beneficial. This allows them to provide a right angle gear drive that will meet the correct power and torque requirements and offer customizations that will help to solve any remaining problems.

Discover Your “Right-Sized” Right Angle Gear Drive Supplier

Finding the right size and power isn’t limited to gearboxes— it applies to vendors as well. While small, 1- or 2-person operations may offer friendly, personable service, they often lack the breadth of capabilities and customization options required to meet the demands of complex equipment. On the other hand, a very large vendor may offer a wide range of off-the-shelf options, but will likely come up short when it comes to personalized, custom support.

At MITRPAK, we pride ourselves on being a 100% employee-owned, ‘just-right-sized’ company. Our fully-customizable MITRPAK right angle gear drives are offered in a wide range of sizes and ratings, and our dedicated engineers and service team are ready to help you identify the perfect fit for your application. Contact us today to speak with an experienced engineer about the MITRPAK for your power and torque requirements.